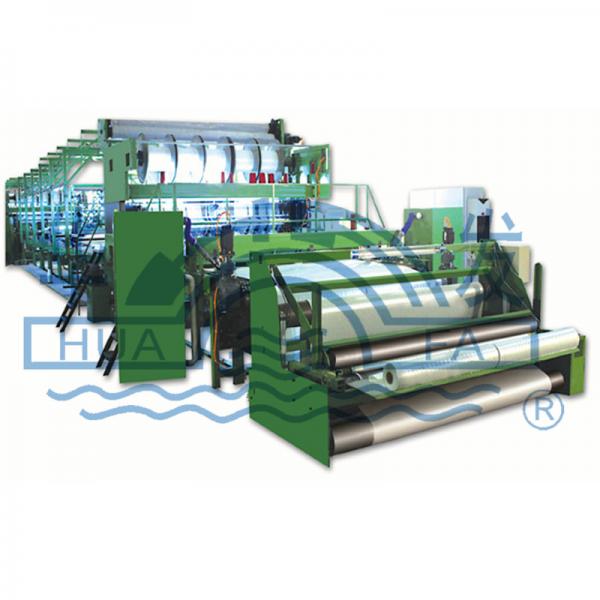

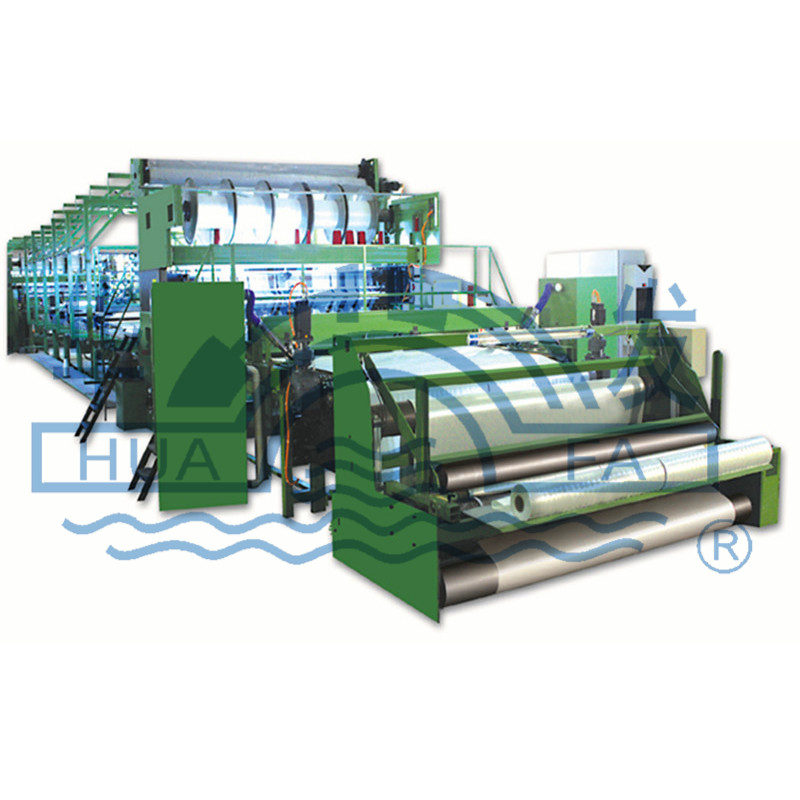

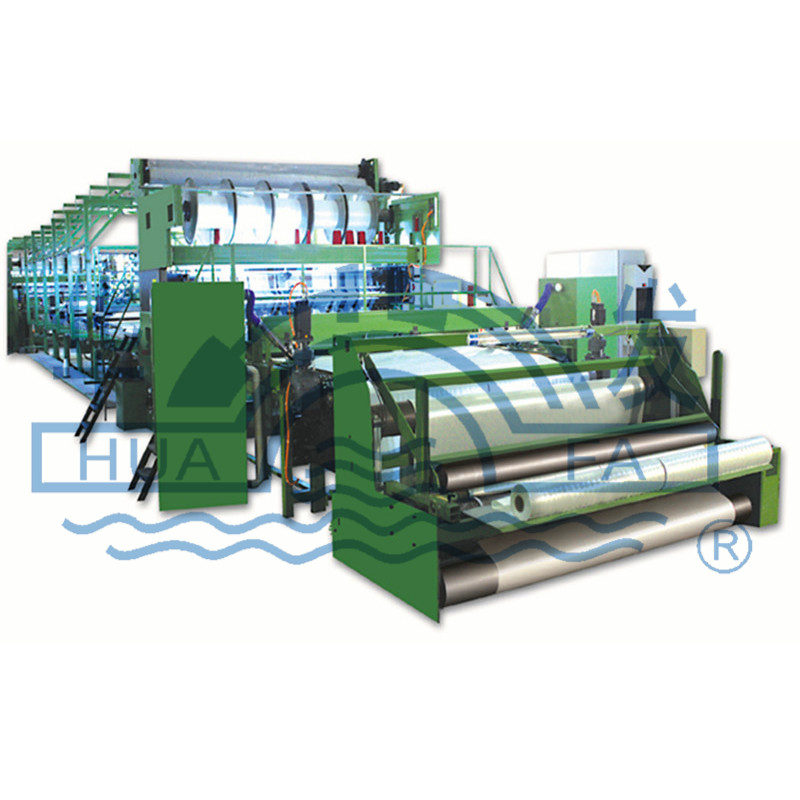

(13 Axis Linkage) Multiaxial Warp Knitting Machine (GE2M-2)

| ≥1Piece | Negotiable |

Basic Info

Product Description

GE2M-2(13 Axis Linkage)Multiaxial Warp Knitting Machine

Introduce for Warping Knitting Machine

It is our new-developed and high performance warp knitting machine which adopts particular compound neddle to decrease the needle resistance to weft yarn.Transmitted hook chain adopts single row hook and 2-5 layers of weft yarn can be spread.The machine adopts real time and double bus distributing mastering and chop mat device can be equipped.The chop mat can be stitched in the fabric construction.

The fabric can be widely use use for many industries such as wind power,sporting goods,spaceflight&aviation,yachts and architecture industry etc.

The fabric can be widely use use for many industries such as wind power,sporting goods,spaceflight&aviation,yachts and architecture industry etc.

Main features for Warping Knitting Machine

1.Real-time dual bus (100MBPS real-time bus Ethernet Power Link and medium-speed bus X2X)9-axis control technology to ensure the 9axis and axis of synchronous operation.

2.Efficient way of short craqnkshaft connecting rod into a circle motiong mechanism,the maximum operating speed up to 1000 rev/min.

3.Shop latitude angle setting flexibility,can be 40°~80°,90°,-40°~-80°range of settings.

4.High-power servo controlled electronic let-off,electronic traction,Electronic take-up.

5.And a new center of friction winding winding winding system for the user to choose two,optional chopped strand mat device.

6.Motion controllers,human machine interface,13-axis servo controller and motor,PLC,power supply,air-conditioned main components such as sub-cabinet Do from Siemens,B&R,Rittal and others imported,to ensure the system's advanced nature,stqability and reliability.

7.Auto trimming,cut pieces of bodies:cell core needle and automatic needle swing mechanism.

8.10.4 inch touch display,parameter display clear,easy to operate,the system protection than the whole.

| Gauges | E5 E6 E7 E10 E12 E14 |

| Working speed | 60 r/min to 1000 r/min |

| Shop latitude | latitude station three shops;Shop latitude angle can be set to 40°~80°,90°,-40°~-80°;to the fabric layers 2-5 |

| Shop weft density | 2C/cm to 8C/cm |

| Shop latitude width | 3-8 inches,shop yarn correction was±10mm |

| The nominal width | 101inches |

| By the axis | The axis drive head size is 30 inches×21 inches;off way EBA |

| Pulling bodies | electronic traction,speed adjustable |

| Take-up mechanism | the friction can speed take-up mechanism |

| Needle-type | Compound needles |

| Guide bar count | 2 |

| Trimming instirutions | Sdjustable blade cutting sgencies |

| Sliding body | Split series faceplate |

| Man-machine interface | eal-time display the main components of the operating parameters:You can modify,save the shop latitude station of process parameters |

| Alarm | The system has a self-diagnostic and alarm function,alarm signals can be displayed in the status line and press the rating for sound and light alarm;system fault alarm log for fault analysis and processing |

| Network protection | a grid voltage undervoltage,overvoltage,phase,phase sequence and a sudden power fault protection functions |

| The password protection function | divided into three grades according to the operation permission |